Sustainability

Sustainable issues, including water processing and management, mine planned closure and social license to operate (SLO) have become more and more critical in acceptable mining. The program addressed a lot research resources to SOL and Finland is in front edge of developing the measures for continuous improvement in mining management, creation of voluntary sustainable mining network being one example.

More information of the Finnish Network of Sustainable Mining

Evaluation of sustainable and acceptable mining is difficult since it has many viewing angles. Comprehensive approach was taken in Sustainable and Acceptable Mining project, (SAM) considering all the main extensions of sustainability in mining: social – environmental – economical.

Planning of mine closure should start already in the beginning of mine development. As a result of the programme a mine closure data bank and “Mine Closure Wiki” has been created.

Water balance management is a challenge in mine operations. WaterSmart project focused on these issues, Management of water balance and quality in mining areas. In Finland we do not suffer from lack of waters, however, the concern is how to protect our ground waters and relatively shallow lakes. In the program a ground water check list was created and published.

Filtering and and measurement technologies are key enablers in sustainable water processing and recycling.

Example cases

Sofi Filtration

Sofi Filtration is a Finnish provider of state-of-the-art water filtration technology

Read moreSofi Filtration

Industries like mineral processing, oil & gas, and power generation face increasing restrictions to fresh water supply and the cost of water is rising.

Automatic and energy efficient microfiltration solutions such as Sofi Filter are emerging technologies for increasing water recirculation rate at production plants. This means less fresh water need, less waste water produced, and pure water in the processes.

Meoline

Meoline has developed first field-compatible real-time trace metal analyzer in the world.

Read moreWatch technology introduction and case video

Meoline Oy is 2015 established Start-up Company. The company has developed first field-compatible real-time trace metal analyzer in the world. The innovative solution has clear advantages over manual sampling followed by lab analyses. The results comes within five minutes and the customer can see the results in Web-based portal 24/7 in anywhere. The system is early warning solution and if the water contains too much metals, the end-customer can start a proper actions to prevent environmental damages. The system has been well tested in harsh Finnish climate.

The analyzer has been developed in University of Oulu during last six years in Tekes funded projects. Last university project contained comprehensive field testing period and many preparative action towards commercialization such as end-customer interviews, market potential surveys and business model planning.

There was a market research in which potential buyers, distributor and government agent were interviewed. Similarly, during the market research, many existing companies (those who have related products) were contacted, many reports were read and online research was also used. The outcome of the research showed that the needs of target markets were:

- Need for environmental monitoring device for the purpose of satisfying environment permit requirement.

- Need for multi-parameters online measurement device.

- Need for reliable and accurate device.

- Need for maintainable device.

The company has identified four clear market segments; mining industry, chemical industry, water utilities and authorities. Today many of those rely on manual sampling and laboratory analysis which are time consuming and also costly. Our trace metal analyzer will be cost-efficient solution for metal monitoring. Today, there are few online measurement devices and most of them are either big (in size) or static and thus they are not suitable for industrial discharge waters.

Meoline has made contract for distribution to Nordic countries and has made the first contracts to Chile. The company is looking for new partners to new market areas and seeks for growth. Meoline Oy won the Kainuu region Kasvu Open competition and was selected to national final in this growth competition.

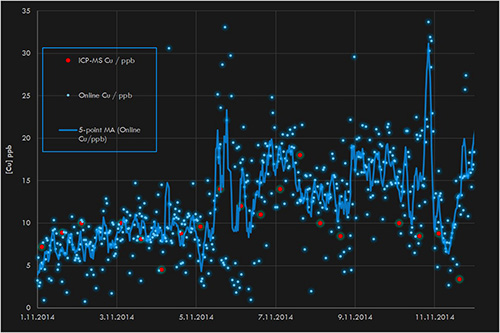

Real-time data vs. laboratory analysis

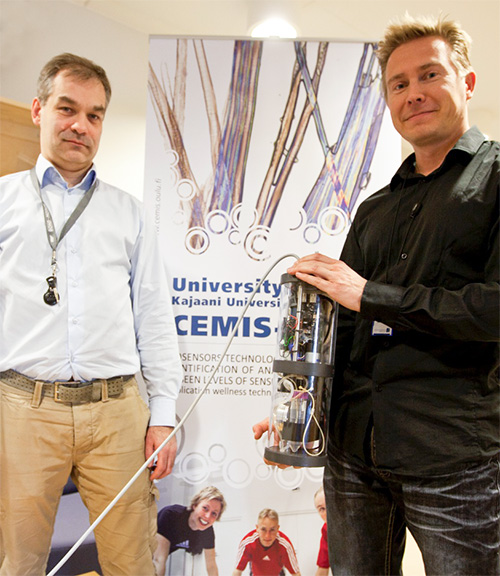

Real-time data vs. laboratory analysis CEO Dr. Jarkko Räty and CTO Mika Mahosenaho with the instrument

CEO Dr. Jarkko Räty and CTO Mika Mahosenaho with the instrument